September 1927

SOME FINE POINTS OF VALVE GRINDING

Late one afternoon, just before closing time, a customer bustled into the combination salesroom and office of the Model Garage. "Got any good valve-grinding paste?" he demanded. "I want the kind that has two compartments -- one with coarse compound and the other with fine."

"I'm sorry, Mr. Rankin," replied Joe Clark, "but we don't carry that kind. Why don't you try the new water-floated paste? Gus Wilson, my partner says it does a dandy job."

"Nope!" Rankin growled. "No substitutes for me! I know what I want." And he left the office.

Gus Wilson, who was working on a car near by, had overheard the conversation. "We never seem to have what that pest thinks he wants," he called out to Joe. "I wouldn't shed any tears if he never came near this place again. But I have a hunch he's going to need us to get him out of trouble one of these days."

"He won't get into trouble this time," laughed Joe. "Valve grinding isn't so hard."

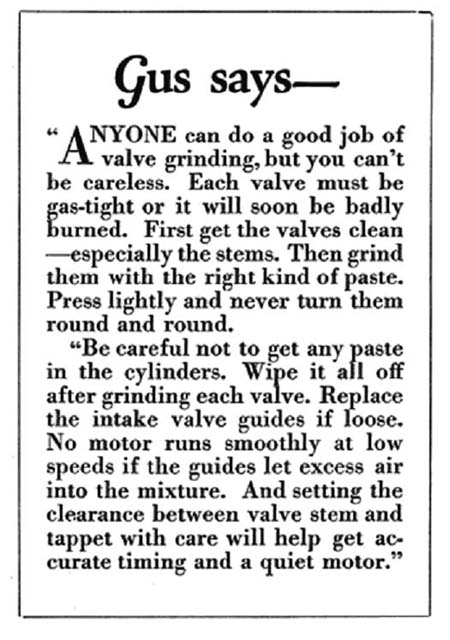

"Huh!" snorted the veteran auto mechanic. "Don't fool yourself. Valve grinding looks easy and it is easy; but you can make plenty of mistakes if you don't know how to go about it."

Two weeks later the phone rang insistently and Joe clamped the receiver to his ear. A moment later he turned from the phone with a grin.

"Get out the wagon, Gus," he called. "Your hunch came true. Rankin's stuck at the bottom of Marley Hill."

Gus drove off in the service car and in half an hour he returned with the disabled machine on his towrope.

"Now let's see what's the matter with those valves, Mr. Rankin," said Gus as he set to work removing the cylinder head after opening the radiator drain cork.

"See here, snapped Rankin, "I'll admit the car is on the blink, but there can't be anything wrong with the valves. Why, I ground'em myself just a little while ago. Gus disconnected the hose connections and removed the cylinder head. Rankin leaned over to look at the valves.

All the exhaust valves appeared badly burned. Several were so warped that they made contact with their seats only at one side. The intake valves, on the other hand were in good shape,

"Those valves must be defective," Rankin stormed. "I'll make the company replace every one of them!"

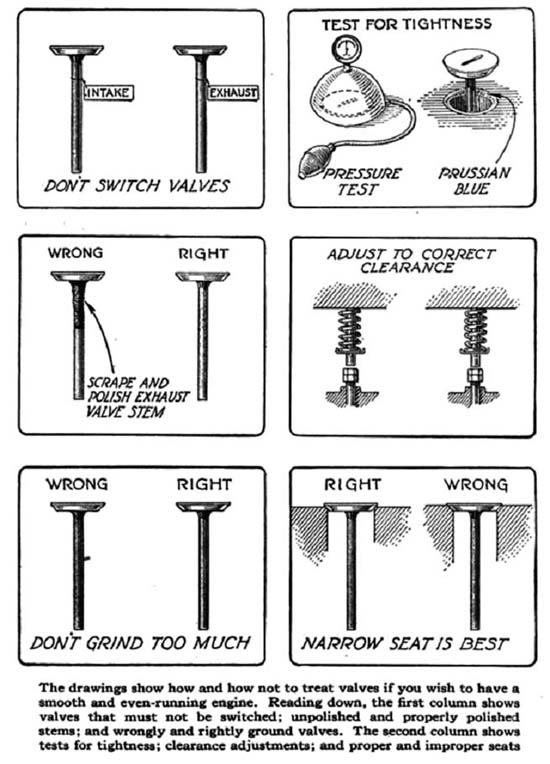

"Not a chance," said Gus calmly. "It's entirely your fault. You put the intake valves in where the exhaust valves ought to be, and the exhaust valves are doing intake duty."

"I did it on purpose," Rankin admitted. "The exhaust valves looked blackened and they were pitted, so I thought I ought to shift them around -- to equalize the wear."

"That's where you went wrong," explained Gus. "A lot of cars these days have plain steel valves for the intake and special exhaust valves that can stand a lot of heat without warping. The manufacturers have to save every penny in order to sell cars at today's prices -- so there's really nothing to criticize. The intake valves have an easy time of it compared with the exhaust valves that are burned with hot gas on every explosion."

Gus removed the valves and the result was quite evident. Both the surfaces of the valves and the faces of the seats were blackened and corroded.

"How many times have you ground these valves?" asked Gus.

"This is the second time," Rankin answered. "The first time I put the valves back as they were."

"You certainly ground'em aplenty," Gus observed, These valves and seats are worn down as much as they would be after ten normal grindings. It isn't necessary to grind so much. You used the coarse grinding paste quite a while before you started to finish them. The more you grind the more you widen out the seat -- and a wide seat is bad. A narrow seat is better, because there isn't so much chance for particles of carbon to jam in between the valve and the face of the seat and keep the valve from closing."

Gus held up a valve. "See that ridge? You've ground the valve against the seat so much that the face is worn away, and there's a ridge around the outside edge. If the valve stem is the least bit loose in the valve guide, that edge is going to catch on the valve seat and prevent it from closing gas-tight. The same things would occur after a number of correct grindings unless you had the valves refaced.

"This valve shows another trouble. The grinding has made the face curved instead of flat. Looks as if the valve guide is loose and the stem wobbled in the guide while you were doing the grinding.

"We've got an electric valve-facing outfit and I'm going to grind the faces of all the valves. That will make them practically as good as new. Also I'm going to ream out the gas passages a trifle, to narrow the seats, so I can true 'em up without making 'em any wider, and replace one of the valve guides."

"Holy smoke!" gasped Rankin, "I must be some mechanic! If ever I try grinding valves again -- "

"I'm not trying to scare you out of working on your car," smiled Gus. "There's no reason why you shouldn't do ordinary valve grinding -- if you go about it right. It isn't necessary to grind the valves on a special machine and reface the seats every time. Such treatment is only needed after a number of regular jobs.

"Valve grinding should be done every time you scrape out the carbon. Don't let it go until the valves leak so bad the motor begins to lose compression and runs rotten. Once the hot gases begin to get past them, the valves burn and pit much more rapidly. Little and often is the rule for best results. Each time you grind the valves, take off just enough metal so that they seat all the way round; and don't forget to scrape the carbon off the face of the valve before you start grinding.

"Apply the paste evenly, don't press hard, and never rotate the valve all the way around. Turn it back and forth through a part of a circle a few times. Then lift it off the seat, turn it part way round and do a little more grinding."

"How do you know when the job is finished?" Rankin inquired. "I ground 'em a lot just to be on the safe side."

"A good mechanic can tell by the feel of the valve and the look of the seat," Gus replied. "If you're very fussy you can buy a pressure tester like this one." He fished an instrument out of his tool kit. It was shaped like an inverted cup with a gage attached to one side and a rubber bulb connected to it with rubber tubing.

"You press the cup over the valve and squeeze the bulb to pump up a bit of pressure," Gus explained. "If the gage needle stands still, you can be sure that no air is leaking through the valve and it will be gas-tight.

"Here's another simple way to test valves. Wipe off all the grinding paste from both the valve and the seat. Rub enough Prussian blue on the ground part to color it and press it tightly in its seat without turning it. Take the valve out again and if you find a complete ring of blue on the valve seat you may be sure the valve is sufficiently gas-tight."

"Maybe I used the wrong kind of grinding paste," Rankin suggested. "The coarse stuff cut fast enough; but it made deep rings in the metal and I had to grind quite a while with the fine paste to get rid of those rings."

"Joe tried to sell you the right kind of grinding paste, but you wouldn't listen to him," Gus reminded him. "You didn't bother to polish the stems, did you?"

"No," Rankin admitted. "I thought the motion of the valve stem up and down in the valve guide would scrape off the carbon if it got too thick."

"Neglecting that point is what spoils a lot of amateur valve-grinding jobs," Gus asserted. "The carbon gets burned on the stems of the exhaust valves so hard that it forms a little ring on the stem just where it interferes with the valve's closing tightly on the seat. First the motor begins to miss when it's idling, finally it gets so bad that the motor will only fire on all cylinders when the throttle is nearly wide open and the compression is high enough to jam the valves shut in spite of the carbon-caked stems.

"The funny thing is that the valves seem to close all right and the compression is fairly good when you crank the motor over by hand. The valve stems cool off when the motor is stopped and they contract enough to work right.

"After grinding valves you've got to adjust them for proper clearance. If you get 'em too close, the valves won't seat right, the motor may start hard and the valves will need grinding again too soon.

"Of course, reducing the clearance between the valve stems and the tappets will make a motor sound nice and quiet especially if the parts are badly worn.

"On the other hand if there is too much clearance the motor will be noisy. It's better, though, to have them a little too loose than a little too tight."

"What's the correct clearance?" Rankin asked.

"Depends on the car," replied Gus. "The service instruction book will tell you what the clearance should be. If you haven't got a book, set the intake valves with about three thousandths of an inch clearance and the exhaust valves at five thousandths -- exhaust valves always need more because they get hotter and the stems expand to a greater length. If it's an overhead valve motor the clearance should be greater -- about five to seven thousandths for the intake valves and from seven to ten thousandths for the exhaust.

"Whatever clearance you use, it's mighty important to have all the intake valves exactly the same; the exhaust valves also should be alike. Then whatever noise is made by the valve mechanism will be smooth and steady. If one valve is a trifle looser than the others you are sure to hear the individual click."

"One other question I'd like to ask," said Rankin. "I've been turning the motor over by hand to find when the valve is closed so I can set the clearance. As soon as I see that the valve is closed I get busy with the adjusting nuts. Is that right?"

"Not quite, "Gus answered. "Turn the motor one half a revolution beyond the point where the valve closes. That is especially important in a motor that has been driven considerably, because when the valve closes the valve tappet snaps down on the cam just past the high part that makes the valve open. This pounding has a tendency to wear the cam at that point and if you do your adjusting while the tappet is resting on the worn spot, there won't be enough clearance on the rest of the low part of the cam.

"Don't forget to inspect the valve springs. Weak springs make the motor run rotten at high speed. The trouble is that a weak spring doesn't close the valve fast enough, so that it stays open when it should be closed. The faster you go the worse the valves work. Of course it is easy to test the spring for weakness, because a weak spring always is shorter than a new one. So just compare your springs with a new one, and discard any that are noticeably short."

"Well, if I do a bum job the next time I grind the valves it won't be your fault," said Rankin as Gus finished his explanation, "and if you folks told me that breakfast food made good valve-grinding compound, I'd almost believe you!"

END

L. Osbone 2019