November 1926

WHEN CARBON CLOGS YOUR MOTOR

by Martin Bunn

Gus Tells How to Burn and Scrape It Out -

Other Repairs That May Be Needed

"Now we'll see how good you are at burning carbon," remarked Joe Clark to his partner, Gus Wilson, as the latter stood back and surveyed the portable carbon burning outfit he had just assembled.

"Humph!" Gus growled. "If everything else around the Model Garage gets done as well as the carbon burning I do, we'll never have any kicks."

"Guess I'm going to be the first customer for the new outfit," called out Arthur Watford as his car rolled up behind the two garage men.

"Howdy, Watford. You want some carbon burning done, I take it," said Gus. "All right, I'll leave your motor running a minute. I want to see how bad it is."

"Pretty well clogged up, I should judge," he continued after speeding up and slowing down Watford's motor several times, meanwhile listening carefully. "One cylinder seems to be a bit worse than the others, but that's nothing unusual. How does she pull on the hills?"

"Not so good," Watford replied. "It doesn't miss any explosions, but it knocks like the dickens if I open the throttle very much, and it hasn't nearly so much power as it should."

"Compression is fine, too," observed Gus as he turned the motor over with the crank. "Well, let's get started."

Gus first placed a fire extinguisher in a convenient place on the running board and then proceeded to remove all the spark plugs and the plate that covered the valve stems.

"You're not aiming to burn up the old bus, I hope," laughed Watford.

"Don't worry," advised Gus. "I haven't had to use the fire extinguisher yet, but you never can tell. An ounce of prevention is worth a lot more than a burned-up auto, so I never take a chance."

"Watch that intake valve and tell me when it starts to close," he instructed, pointing to the intake valve on the first cylinder as he slowly cranked the motor. Watford called a second later.

"All right," said Gus, "come around here and turn the motor over real slow until I tell you to stop."

Gus inserted a piece of stiff wire in the spark plug hole far enough to touch the top of the piston, pulling it out gradually as the piston traveled upward. When it reached the top he signaled Watford to stop turning the crank.

"Now for the burning," said Gus as he turned on the oxygen and threw a lighted match into the spark plug hole, following it with the end of the copper pipe from which a stream of oxygen was flowing.

A roaring flame immediately shot out of the spark plug hole.

"That's just the oil burning up," Gus explained. "As soon as that is all gone the carbon will take fire. See the sparks coming out now. That's the carbon."

Gus kept the end of the pipe moving so that the gas was sent to every part of the cylinder head and the top of the piston. The quantity of sparks grew less, and finally the glow went out.

"That cylinder is as clean as you can get it by burning," observed Gus as he went around to the front of the car again and turned the crank exactly one third of a revolution. "You don't have to use the wire to find top center for the other pistons after the first. All you do with a six cylinder motor is turn it over a third of a turn and then burn the next cylinder according to the firing order. See those numbers molded into the side of the crank case? No. 5 comes after No. 1, so we burn No. 5 next.

"Four-cylinder motors can be done in the same way, only you turn the crank halfway around each time and with eight cylinders you give it a quarter turn."

"How do you know the valves will be shut?" questioned Watford.

"That's easy, replied Gus. "The valves are always closed when the cylinder is ready to fire, so if you get it to the firing point you are bound to be right."

"Seems to me I've heard it's not a good idea to burn out the carbon in a motor that has a detachable head," Watford said. "They claim it is likely to injure the gasket. How about it?"

"It won't be damaged if you are careful and don't try to do the job too quick, and if you keep the oxygen pipe moving all the time. I never had any trouble that way."

After Gus had finished burning all six cylinders, he replaced the spark plugs, connected the wires to them, and started the motor. It sputtered and ran unevenly for a few moments. "She'll run smooth as soon as all the loose particles of carbon have been blown out through the exhaust valves," he explained as Joe handed Watford his change.

As Watford drove off up the road Joe noticed another car coming in the opposite direction. "Here's old man Burdett again," he exclaimed. "I suppose he's got a couple of complaints in his system as usual."

Joe's prediction was partly right, for Burdett stopped in front of the Model Garage. But he didn't register any kicks.

"Somebody told me you were going to put in a carbon burning outfit – " he began, and then he spotted the new apparatus. "I see you have it already. I want this motor burned out right away. It's just loaded with carbon. Can you fix me up?"

"Sure I can," replied Gus, "but not by burning out the carbon. From the way that motor is running there is a whole lot wrong beside too much carbon and it would still run rotten even if I did give it a burning out."

"Is that so! Growled old Burdett. "It's the carbon that's making it run rotten, I tell you, and if you burn that out I'm sure it will be all right."

"But burning the carbon only cleans out the cylinders," Gus protested. "Your valves are sticking because there is carbon caked on the stems, and the oxygen doesn't cure that trouble at all. And if the valves have been sticking for any length of time they're sure to be pitted bad enough to need regrinding.

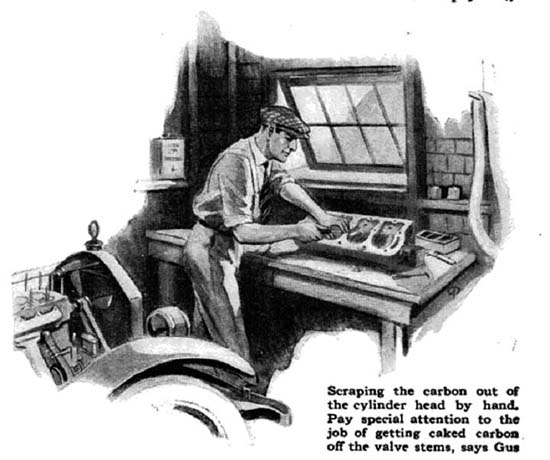

"Burning out the carbon is worthwhile only when the motor is otherwise all right. For your motor, the best way will be to take off the cylinder head, scrape out the carbon by hand and grind the valves, paying special attention to getting the caked carbon off the stems."

"Yes, and you'll want about a million dollars to do that job," snapped Burdett. "I guess I'll do it myself."

"Why not?" Gus suggested amiably. "It isn't very difficult even if it does take time and gets your hands dirty. You don't even need any special tools except a valve lifter and some grinding compound. And we have a valve lifter in stock that will only cost you the price of burning two cylinders."

The idea seemed to appeal to Burdett, for he went into the office with Joe and came back in a few minutes with a package under his arm.

"How do I get started?" he asked.

"First, drain the radiator," Gus told him. "Then take off the top hose connection, the one that goes to the cylinder head. Your motor has the valves at the side, and that means that both the intake and exhaust manifolds are bolted to the cylinder block. If you had an overhead valve motor you would have to take them off too.

"After that get out the wrenches and loosen up all the cylinder head bolts about two or three turns. Then step on the self-starter and let the motor turn over a few times. The compression will loosen up the head if it happens to be stuck tight. Get busy with the wrench again and take out all the spark plugs and the cylinder-head bolts and then lift the cylinder head off."

"Isn't it pretty heavy?" Burdett asked.

"You can lift it easily enough," replied Gus. "You see it is all hollowed out for the cooling water so it's not nearly so heavy as it looks.

"Scrape all the carbon out of the cylinder head with an old screwdriver. Then scrape off the top of the pistons, one after the other, and be sure to cover up the bolt holes and the cylinders you are not working on to keep the scrapings from clogging things up.

"You get the valves out this way," Gus continued as he took off the plate on the side of the motor and showed Burdett how to use the valve lifter. "Watch out you don't lose the pins and be extra careful not to mix up the valves. They all look alike, but the exhaust valves on this car and on some other makes are made of tougher material than the intake valves, and if you get them switched around the motor will run right for about a week and then the misplaced valves start to warp and you will have to do the job of grinding them all over again.

"Don't use too much grinding compound and don't press too hard on the valves and you will find that the water-floated grinding compound Joe sold you will do a fine job in no time at all. Be sure to get all the caking off the valve stems and polish them as bright as possible."

"Huh!" Grunted Joe after he had gone. "I suppose he thinks we guarantee the job just because you gave him a few instructions. Why didn't you argue him into letting you do it?"

"Don't worry," Gus grinned. "Burdett hates to get his hands dirty, and after he has spent about a week trying to get the dirt off 'em from that job, he'll come around the next time and have us do it!"

END

L. Osbone 2019